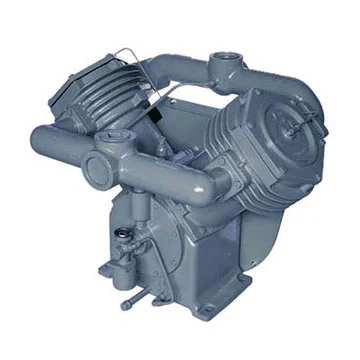

Reciprocating Compressor & Vacuum Bares 11.2-30kW (15-40hp)

The A-series reputation has been built on quality, reliability and accessibility to all components. Products include air-cooled bare compressors, boosters and vacuum pumps. A-Series compressors include heavy duty cast iron construction, counterbalanced crankshaft to ensure smooth operation, deep-finned cylinders and heads, which quickly dissipate the heat of compression. Superior lubrication is accomplished through a gear driven positive displacement oil pump powered by the crankshaft. A-series bares and boosters are ideal for petroleum refineries, oil rigs, plant air and vacuum, ore mines, engine starting and well head servicing.

Specifications and Features

- 15-40 hp (compressor or booster)

- Up to 350 psig operating pressure

- Single & Two Stage

- Pressure Lubricated

- Heavy-duty cast iron construction

- Factory filled with AEON lubricant

- Compressor or Vacuum Pump with spin-on oil filter

- Drive sheave with turbo fins

- Oil level dipstick

- Suction unloading valves (SUV) or plain valves as indicated

- Factory fill of Champ Lub AC

- Two-Stage include Intercooler with pressure gauge and relief valve

- *ANP Natural Gas Compressors have no exposed brass or copper components.

*ANP Natural Gas Compressors include Viton o-rings and threaded crankcase vent connection.”

- ASME pressure relief valve protects the intercooler and first stage from over pressure.

- Suction unloading valves (where applicable) provide loadless starting and stopping as well as quick response to capacity demands.

- Removable hand-hole plate allows easy access to the internal running gear.

- Tri-Metal insert bearings are two-piece for quick and easy replacement.

- Counterbalanced crankshaft assures smooth operation.

- Replaceable piston pin bearings are very economical when replacement becomes necessary.

- Generously sized intercooler provides maximum cooling for the most efficient operation and low power consumption. (AVLAVCAA only)

- Deep-finned cylinders and heads quickly dissipate the heat of compression.

- Crankshaft ends are supported by large tapered roller bearings for smooth operation and long life.

- Oil pressure gauge assures the operator of lubrication system integrity.

- The cylinders and crankcase are built of industrial strength cast iron materials.